How Precision Machined Parts and Rapid Prototyping Are Transforming Modern Race Car Manufacturing

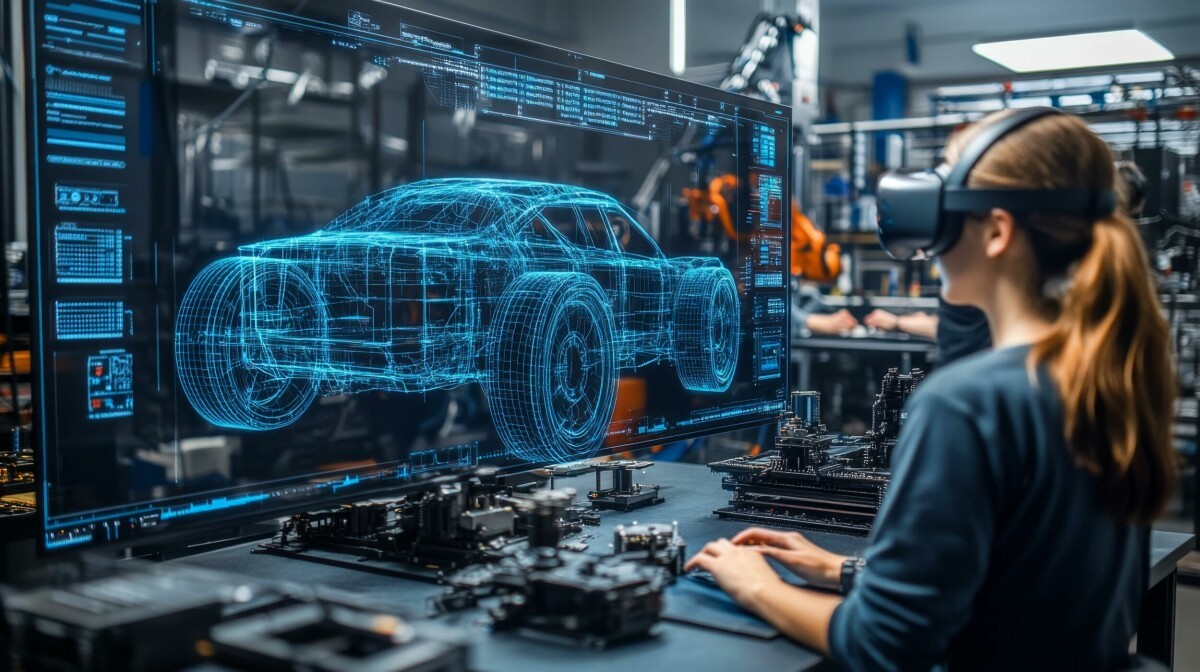

Motorsport is a world where milliseconds matter. A fraction of a second can separate the champion from the pack, and behind every high-performance machine on the grid lies a long chain of engineering decisions, prototyping stages, and component optimization. As racing evolves, so does the technology that powers it—and nowhere is this more evident than in the rise of precision machined parts and Rapid Prototyping.

From F1 and IndyCar to NASCAR and endurance racing, elite teams are now relying on advanced manufacturing capabilities to push the limits of speed, safety, and aerodynamic performance. The days of slow machining cycles and trial-and-error fabrication are fading. Today, the racing industry is fueled by an engineering ecosystem built on faster iterations, tighter tolerances, and smarter production workflows.

In this article, we’ll explore how a new wave of advanced manufacturing is shaping the future of race car development—from concept design to track-ready performance.

The Need for Engineering Speed in Motorsports

Racing teams don’t have the luxury of long production schedules. New parts need to be tested, redesigned, optimized, and installed in record time—especially during a competitive season.

Every race weekend introduces new data points:

- aero inefficiencies

- heat-related component failures

- higher cornering loads

- unexpected vibrations

- driver feedback

To stay ahead, teams need engineering speed just as much as engine power. That’s where Rapid Prototyping has become a competitive advantage.

Instead of waiting weeks to test a new wing mount or brake duct, engineers can now produce prototypes overnight. Coaches, mechanics, and aerodynamicists get real parts they can mount, inspect, and validate at hyper-speed. And if the part needs modifications? Another iteration can be ready in hours.

This fast feedback loop is reshaping how racing teams attack performance problems.

Rapid Prototyping: The New Backbone of Race Car Innovation

Rapid Prototyping gives race teams the freedom to experiment quickly — and safely. Using advanced 3D printing and low-volume production techniques, teams can generate:

- aerodynamic prototypes

- interior cockpit components

- cooling channels

- steering wheel housings

- intake ducts

- sensor brackets

And these aren’t just basic plastic models anymore. The materials have evolved to include high-temperature polymers, nylon composites, carbon-infused materials, and in some cases metal-ready prototype structures.

For race engineers, the benefits include:

1. Faster Design Testing

New aerodynamic add-ons, like winglets or bargeboard textures, can be physically tested in wind tunnels the same week they are designed.

2. Better Data Collection

Prototypes help teams quickly validate structural feasibility before investing in full CNC machining runs.

3. Reduced Risk

Teams avoid wasting costly materials by validating fit, airflow behavior, and driver ergonomics during the early stages.

The motorsport industry is built on continuous improvement — and Rapid Prototyping accelerates that improvement cycle.

Precision Machined Parts: Where Performance Meets Perfection

Once a part is ready for final production, teams turn to their most trusted process — CNC machining. The racing world demands parts that can withstand insane loads, extreme heat, violent acceleration forces, and micro-vibrations at over 300 km/h. There is zero margin for error.

This is where Precision Machined Parts come in. These components deliver:

- sub-millimeter accuracy

- perfect surface finishes

- consistent performance

- race-grade durability

Whether it’s a titanium suspension component, an aluminum gearbox housing, or a carbon-fiber reinforced bracket, CNC machining ensures every part meets exact engineering specifications.

In motorsports, precision engineering directly translates into competitive advantage.

Where Rapid Prototyping Meets CNC Machining in Racing

Modern race car development relies on the combination of both processes. Here’s how teams typically use them together:

Step 1: Design & Simulation

CAD modeling, digital crash tests, airflow simulations.

Step 2: Rapid Prototyping

Engineers quickly print physical parts to validate:

- size

- ergonomics

- airflow

- heat resistance

Step 3: Physical Testing

Wind tunnel trials, track tests, and stress analysis.

Step 4: Precision CNC Machining

Once validated, the final part is produced using aluminum, titanium, stainless steel, or other race-grade alloys.

Step 5: Installation & Race Day Performance

The part is mounted, calibrated, tested — and eventually trusted at full race pace.

This hybrid workflow is one of the reasons today’s cars are faster, lighter, safer, and more aerodynamic than ever before.

How These Technologies Are Changing Race Day Strategy

It’s not only pre-season engineering that benefits. During a race season, teams often face unexpected challenges:

- a cooling duct cracks

- a suspension arm needs reinforcement

- the aero package needs tuning for a specific track

- a new regulation demands component redesign

- a crash damages structural parts

In the past, teams were limited by what they brought to the track. Now, with portable prototyping units and fast-turnaround manufacturing partners, teams can redesign and produce new parts even between back-to-back race weekends.

This capability is reshaping how teams manage reliability and performance under pressure.

A New Era of Race Car Manufacturing

The combination of Rapid Prototyping and Precision Machined Parts is more than just a technological advancement — it’s a competitive weapon. Racing teams that embrace faster production cycles and more accurate components gain:

- improved aerodynamics

- reduced vehicle weight

- better heat management

- stronger structural integrity

- more efficient testing programs

- rapid incident recovery

Today’s race cars are engineering masterpieces not only because of their engines or electronics, but because of the advanced manufacturing that powers their evolution.

Motorsports has always been a proving ground for technology. Now, modern fabrication is proving itself as one of the most important tools in the race for speed.