Brembo explains innovations of Formula 1 2021 Championship

Brembo reconfirms its commitment in the Formula 1 World Championship which will start with the Bahrain Grand Prix, scheduled this year on 27th – 28th March. Thanks to the experience accumulated in 46 Formula 1 seasons, during which the single-seaters with Brembo brakes achieved 26 Drivers World Championships, 30 Manufacturers World Championships and 442 Grand Prix wins with Brembo designed braking systems personalized for each team, Brembo will supply most of the single-seaters between hydraulic materials and friction components.

In line with the current protocols of Formula 1 and with the measures to contain the COVID-19 pandemic, Brembo will continue to provide assistance to the teams competing in 2021 by limiting their presence at the track while making use of the Brembo Remote Garage. Introduced in 2020 at the company’s Curno headquarters, it’s a highly technological solution which became necessary after Formula 1 decided to minimize access to the track and prohibit contact between people belonging to different teams. This made it impossible for Brembo engineers to assist the teams on the track.

In Curno, the Brembo Remote Garage works at full capacity every race weekend, with at least two engineers in the hall, high-capacity computers, dedicated lines for receiving data, large screens to follow live broadcasts and applications with which to hear radio messages between boxes and drivers on the track. As soon as the COVID-19 emergency allows it, the goal is to return to the track at the company’s usual full service capacity, alongside the Brembo Remote Garage, for the most complete service to our racing customers.

A view to 2022

From the point of view of the braking systems, the 2021 championship does not present significant changes compared to the 2020 season, given the freeze imposed on some components of the cars, including the braking system.

In 2022 the Formula 1 regulations will undergo a substantial change. One of the most visible changes that will attract the attention of professionals, enthusiasts, and fans will be the transition to 18-inch wheels and tires. The increase from the current 13-inch to the future 18’s will create more space for the brake housing within the rim and for this reason the regulation has adapted to allow larger dimension brake discs.

The external diameter of the carbon discs will go from the current 278 mm to a maximum of 330 mm, with an unchanged maximum thickness remaining at 32 mm. Teams will also be imposed on the use limit of a single set of discs and pads – consisting of 4 discs and 8 pads between the front and rear axles – for each GP, this will entail a further challenge for Brembo in the development of its friction materials. With an increase in the effective radius, Brembo will have to review the architecture of the discs as well as the geometry of the calipers, pads and pumps.

Another important change concerns the components of the wheel corner such as the air intakes and baskets which will be “prescribed components,” the same for all cars. This will limit the possibility of using these components as elements to increase the aerodynamic load, placing the cooling of the braking system at the center of their function.

The regulation will also affect the ingenuity of Brembo designers, especially as regards the cooling of the discs, whose holes must have a minimum diameter of 3 mm, while currently there is no minimum limit imposed by regulations. This means that with the same disc thickness, holes larger than the current ones must necessarily be fewer, reducing the possibility of cooling.

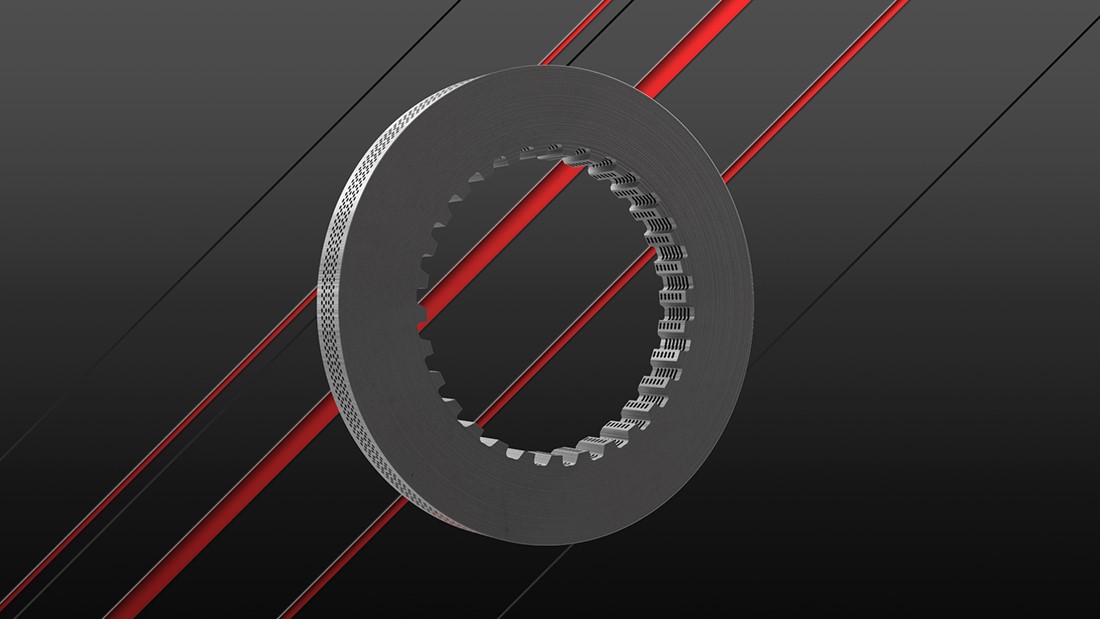

Six options of carbon discs

For the 2021 championship, the majority of the cars will use front discs with 32 mm thickness and rear discs with 28 mm. Depending on the temperatures expected during a Grand Prix (that can reach peaks of up to 1,200 degrees) and the specific race strategy, each driver can choose from six different options of Brembo discs. In addition, each specification is also presented with a process on the external diameter, called “groove” that creates a section diverging from the air which in turn comes out of the disc’s ventilation holes. This geometry allows for greater material cooling efficiency.

For the front braking system, are confirmed three disc solutions:

– the 1480 holes disc is the most extreme solution, called “Very High Cooling” arranged on 7 rows

– the 1250 holes disc solution called “High Cooling” arranged on 6 rows

– the 800 holes disc solution called “Medium Cooling” arranged on 4 rows

For the rear braking system, are confirmed two disc solutions:

– the 1250 holes disc solution called “High Cooling” arranged on 5 rows

– the 800 holes disc solution called “Medium Cooling” arranged on 3 rows

The result is a total of six different ventilation specifications only for the front axle and two different ventilation specifications for the rear axle.

More extreme research of lightness

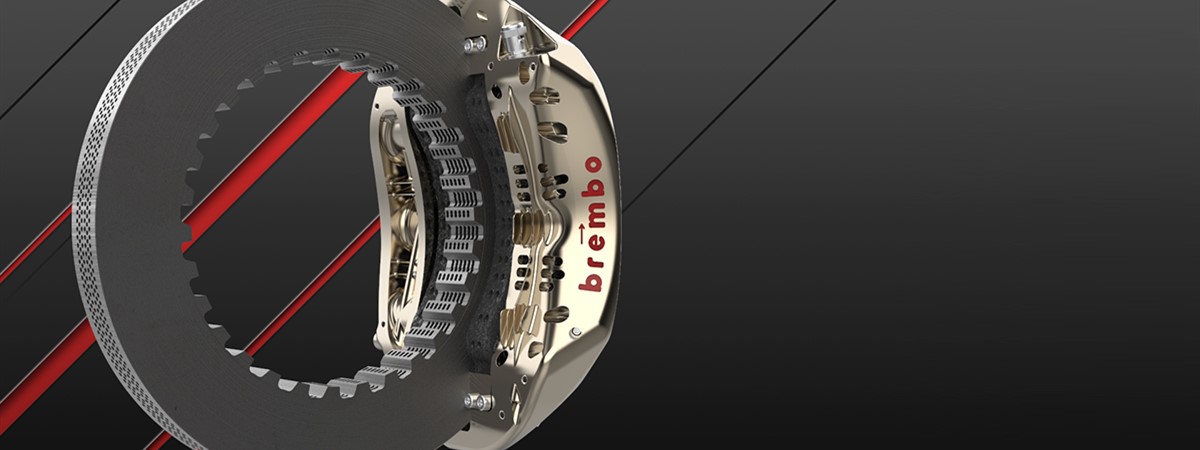

Brembo continues to work on the braking system with a specific focus on the maximum miniaturization of the elements composing the Brake-by-Wire (BBW) system and the further lightening of aluminum-lithium calipers.

Brembo will supply the traditional 6-piston calipers, maximum value established by the regulation, to 8 teams out of 10.

At the same time the Bergamo-based company has tried to increase the system promptness of response and thus the reactivity of BBW units: the integration level with the cars is always greater and in 2021 there will be 4 teams to use Brembo BBW.

Customization, telemetry and maintenance

Each team, according to the specific needs of the car, together with Brembo technicians, define the optimal ratio between weight and stiffness that the brake calipers must have. The sophisticated design methods available for Brembo engineers will make it possible to design for each team a brake caliper model that will optimize the desired weight-stiffness ratio. In this situation some teams will prefer lighter but also less stiff calipers, while others will opt for more conservative solutions characterized by a greater stiffness but also increase weight. This delicate balance allows Brembo to develop the braking system in a totally autonomous way.

Using the sensors, the teams know, in every moment, the temperature of discs and calipers. In this way they are able to calculate instantly disc and pad wear. Evaluating the data, technicians are able to give the driver any indications to adjust the brake balance of the car. This happens when anomalies are found. As for carbon pads, for 2021 Brembo offers teams a choice of two different compounds.

On average, each team orders from 10 to 15 sets of Brembo calipers per year. This number allows to safely face any accidents and the lack of availability of some sets for revision. Some teams, on the other hand, proceed initially to a reduced order, foreseeing a development during the season and then a subsequent order of additional optimized calipers.

On circuits with a lot of brake zone in sequence, the temperature of the calipers reaches 200°C. The useful life of a Formula 1 caliper does not exceed 10.000 km, during which periodic revisions are scheduled and carried out directly by Brembo inside of its production departments.

As regards to friction material, during the season Brembo supplies each team from 150 to 300 discs and up to 600 brake pads.