Automotive News: Vacuum Pump – How It Works and Why rebuilding it saves you money

The vacuum pump is an important element of modern automobile engines, especially diesel and turbocharged gasoline engines. The vacuum pump’s operation ensures stable vacuum levels across brake boosters, turbine control valves, exhaust gas recirculation systems, and other devices that require accurate pressure. A pump malfunction can reduce braking efficiency, increase fuel consumption, and even cause engine instability. In such situations, the best option is to choose a vacuum pump rebuild kit over a new pump.

How a Vacuum Pump Works

A vacuum pump is a device that reduces pressure by altering the volume of the air chamber in the mechanism. The most widely used are rotary vane and diaphragm vacuum pumps.

The rotary vane type operates on the principle of a rotor with movable blades, which create chambers of different volumes that generate a vacuum.

The diaphragm type works by using a flexible membrane that oscillates, expanding and contracting the internal volume.

All these mechanisms are constantly subjected to mechanical friction, high temperatures, and prolonged exposure to engine oil, which inevitably causes wear and loss of tightness.

Common Vacuum Pump Failures

Over time, characteristic problems begin to appear in a vacuum pump:

- Engine oil leakage. The primary cause is hardened or deformed seals. Oil can get on the housing or adjacent engine elements.

- Pressure drop. Worn blades, membrane cracks, or damaged rings lead to insufficient vacuum. This affects the operation of the brake booster and auxiliary systems.

- Damaged membrane. In diaphragm pumps, the diaphragm is the most vulnerable component. Even a small crack can significantly reduce the pump’s efficiency, sometimes by more than 50%.

- Contamination inside the mechanism. Dirt, soot, wear products, or thickened oil create additional friction and can block the movement of the main elements.

Ignoring these symptoms can lead to complete pump failure, which is especially dangerous for the brake system.

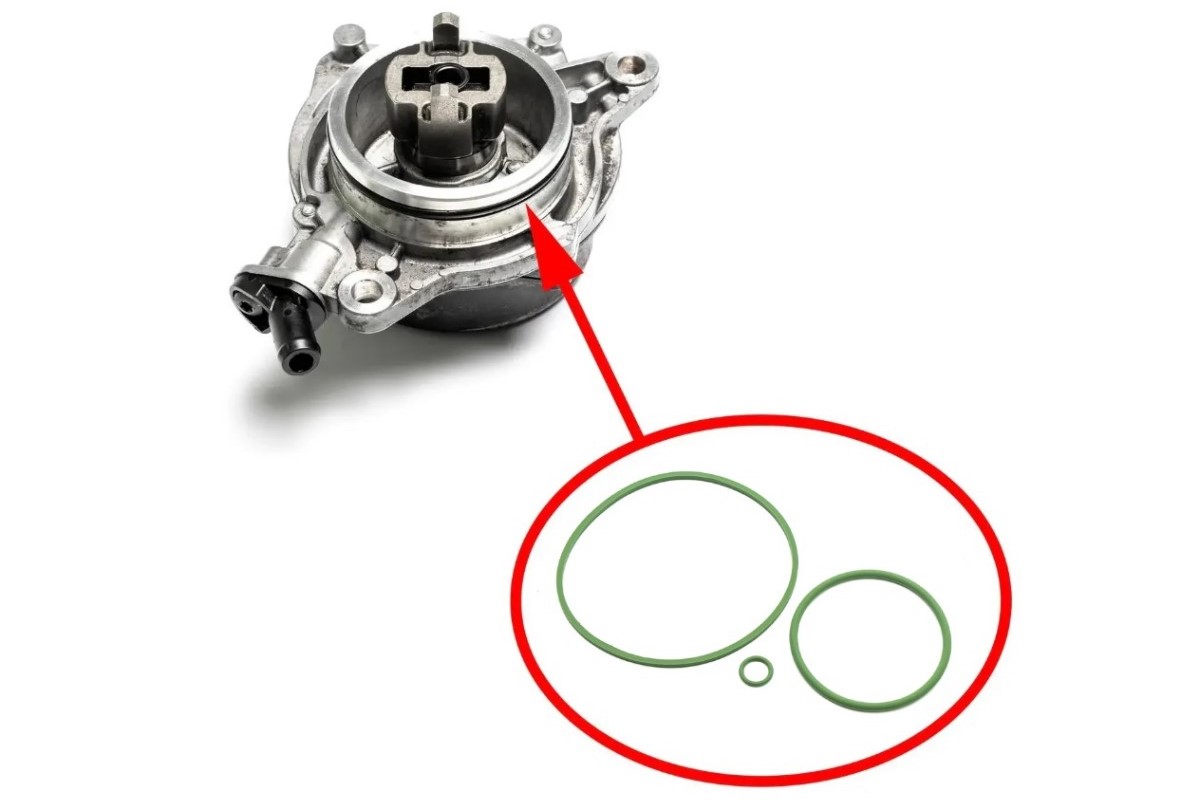

What’s Inside a Vacuum Pump Rebuild Kit

The repair kit is designed to renew all elements responsible for tightness and stable operation. The kits usually include:

- Membranes or service elastic components.

- O-rings and cuffs of various diameters.

- Housing gaskets for complete restoration of mating surfaces.

- Bolts or screws that replace worn fasteners.

- Teflon or metal rings are important for rotary vane pumps.

- Mini-filters or meshes, when included in the pump’s design.

The presence of a complete set ensures no further purchases are necessary and that the unit is restored to high quality.

How to Rebuild a Vacuum Pump

Rebuilding a pump with a repair kit is not at all complicated, but it does require meticulous, neat work:

- Dismantling. The first thing to do is remove the vacuum hoses, then take out the pump from the engine (keep it in the upright position so no oil leaks).

- Disassembling the housing. Twist the bolts out gently and separate the housing’s two parts. Remove the old seals, membrane, filter, and other components.

- Cleaning the surfaces. While using a cleaner specifically for engine parts, remove deposits and old gasket residue. Focusing on frictional areas and oil channels would be wise.

- Installing new components. Out of the kit, put on the membrane, rings, and gaskets. It is recommended to lightly lubricate the seals with a thin layer of approved oil or silicone grease, if allowed by the manufacturer.

- Assembling the pump. The housing is tightened with new bolts from the kit. Tighten evenly to avoid housing distortion.

- Inspection and testing. Once the unit is installed on the engine, start it and measure the vacuum with a special pressure gauge. Perform the leak test and listen for any unwanted noises.

Following these steps allows you to return the pump to almost factory characteristics.

Benefits of Rebuilding vs. Replacing

- Economy. A new vacuum pump can cost several times as much as a repair kit. Restoration significantly reduces costs.

- Preservation of the original part. OEM pumps usually have higher-quality materials and more accurate geometry. The repair kit allows you to “reanimate” these advantages.

- Long service life. Replaced seals and membranes return the pump to reliable operation for a long time.

- Less waste. Restoration is a method that is considerate of nature because it minimizes both scrap metal and the need for new resources.

A vacuum pump repair kit allows you to efficiently and cost-effective restore a vital engine part, making it a very effective solution. Understanding the pump’s principle of operation, performing timely diagnostics, and properly using repair kits ensure a stable vacuum, safe brake operation, and proper engine control system operation. Choose high-quality repair kits that meet OEM requirements to achieve maximum reliability and performance.