GM Reveals New Ultium Batteries and a Flexible Global EV Platform

|

| Modular Battery Pack Design |

Starting today, General Motors Co. (NYSE: GM) is gathering hundreds of employees, dealers, investors, analysts, media and policymakers to share details of its strategy to grow the company’s electric vehicle (EV) sales quickly, efficiently and profitably.

“Our team accepted the challenge to transform product development at GM and position our company for an all-electric future," said Mary Barra, GM chairman and CEO. “What we have done is build a multi-brand, multi-segment EV strategy with economies of scale that rival our full-size truck business with much less complexity and even more flexibility."

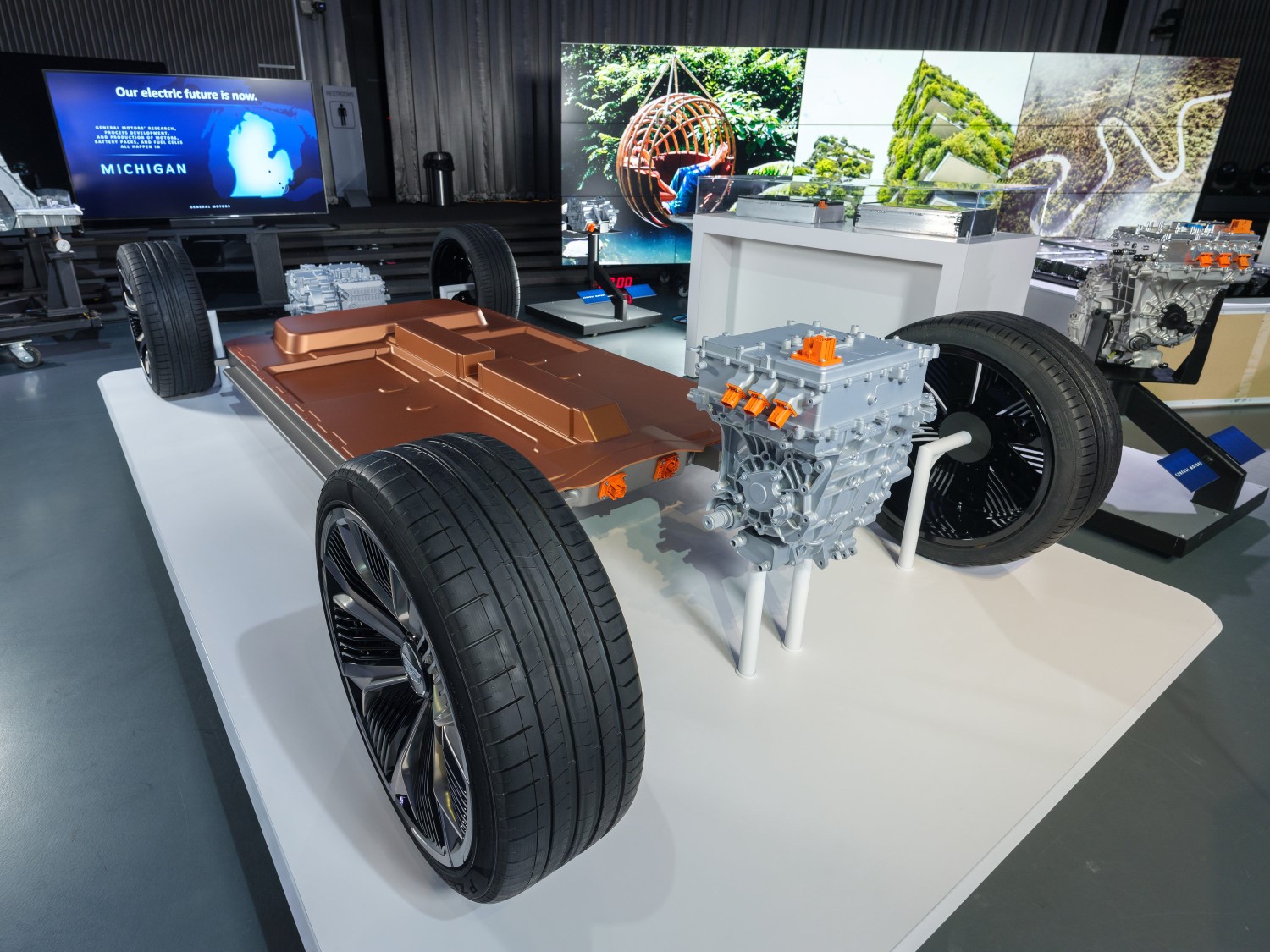

The heart of GM’s strategy is a modular propulsion system and a highly flexible, third-generation global EV platform powered by proprietary Ultium batteries. They will allow the company to compete for nearly every customer in the market today, whether they are looking for affordable transportation, a luxury experience, work trucks or a high-performance machine.

“Thousands of GM scientists, engineers and designers are working to execute an historic reinvention of the company," said GM President Mark Reuss. “They are on the cusp of delivering a profitable EV business that can satisfy millions of customers."

Ultium Batteries and Propulsion System Highlights

- GM’s new Ultium batteries are unique in the industry because the large-format, pouch-style cells can be stacked vertically or horizontally inside the battery pack. This allows engineers to optimize battery energy storage and layout for each vehicle design.

- Ultium energy options range from 50 to 200 kWh, which could enable a GM-estimated range up to 400 miles or more on a full charge with 0 to 60 mph acceleration as low as 3 seconds. Motors designed in-house will support front-wheel drive, rear-wheel drive, all-wheel drive and performance all-wheel drive applications.

- Ultium-powered EVs are designed for Level 2 and DC fast charging. Most will have 400-volt battery packs and up to 200 kW fast-charging capability while our truck platform will have 800-volt battery packs and 350 kW fast-charging capability.

GM’s flexible, modular approach to EV development will drive significant economies of scale and create new revenue opportunities, including:

- Continuous Improvement in Battery Costs: GM’s joint venture with LG Chem will drive battery cell costs below $100/kWh. The cells use a proprietary low cobalt chemistry and ongoing technological and manufacturing breakthroughs will drive costs even lower.

- Flexibility: GM’s all-new global platform is flexible enough to build a wide range of trucks, SUVs, crossovers, cars and commercial vehicles with outstanding design, performance, packaging, range and affordability.

- Capital Efficiency: GM can spend less capital to scale its EV business because it is able to leverage existing property, including land, buildings, tools and production equipment such as body shops and paint shops.

- Complexity Reduction: The vehicle and propulsion systems were designed together to minimize complexity and part counts beyond today’s EVs, which are less complex than conventional vehicles powered by internal combustion engines. For example, GM plans 19 different battery and drive unit configurations initially, compared with 550 internal combustion powertrain combinations available today.

- Rising Customer Acceptance: Third-party forecasters expect U.S. EV volumes to more than double from 2025 to 2030 to about 3 million units on average. GM believes volumes could be materially higher as more EVs are launched in popular segments, charging networks grow and the total cost of ownership to consumers continues to fall.

- New Sources of Revenue: By vertically integrating the manufacture of battery cells, the company can reach beyond its own fleet and license technology to others.

The first generation of GM’s future EV program will be profitable. The initial programs will pave the way for further accretive growth. GM’s technology can be scaled to meet customer demand much higher than the more than 1 million global sales the company expects mid-decade.

Upcoming Launches and Reveals

Chevrolet, Cadillac, GMC and Buick will all be launching new EVs starting this year. The next new Chevrolet EV will be a new version of the Bolt EV, launching in late 2020, followed by the 2022 Bolt EUV, launching Summer 2021. The Bolt EUV will be the first vehicle outside of the Cadillac brand to feature Super Cruise, the industry's first true hands-free driving technology for the highway, which GM will expand to 22 vehicles by 2023, including 10 by next year.

The Cruise Origin, a self-driving, electric shared vehicle, shown to the public in January 2020 in San Francisco, was the first product revealed using GM’s third generation EV platform and Ultium batteries. Next will be the Cadillac Lyriq luxury SUV in April. Details about its launch will be shared then. The reveal of the Ultium-powered GMC HUMMER EV will follow on May 20. Production is expected to begin in Fall 2021 at GM’s Detroit-Hamtramck assembly plant, GM’s first assembly plant 100 percent dedicated to EV production.

Battery Platform

|

|

GM’s highly flexible, third-generation global EV platform powered by proprietary Ultium batteries

will allow the company to compete for nearly every customer in the market today.

• The same platform and propulsion system can power affordable transportation, luxury vehicles,

work trucks and high-performance machines.

• Vehicles built on this modular platform will offer a GM-estimated driving range of up to 400

miles or more on a full charge, 0 to 60 mph acceleration as low as 3.0 seconds, and a battery

energy storage ranging from 50 to 200 kWh.

• GM plans 19 different battery and drive unit configurations initially, including horizontal and

vertical stacks, to power vehicles ranging from affordable cars and crossovers to luxury SUVs and

pickup trucks.

• Motors designed in-house will support front-wheel, rear-wheel, all-wheel and performance

all-wheel drive applications.

Space-efficient packaging that maximizes room for passengers and cargo.

• In North America, GM EVs will be powered by rectangular, pouch-style battery packs that are

simple, lightweight and space-efficient.

• GM’s ability to stack batteries vertically is unique in the industry and it allows for a flat

cabin floor and more interior room than comparable EVs that use cylindrical battery packs.

• The pack also allows engineers to deliver vehicles with an optimized weight distribution and a

lower center of gravity to improve ride and handling.

A unique, low cost battery chemistry and easy to manufacture design.

• GM’s new Ultium batteries will have the highest nickel and lowest cobalt content in a large

format pouch cell.

• Large format pouch cells require less wiring and plumbing than small cylindrical cells.

• Our battery management system is built in, which eliminates 80 percent of the battery pack’s

wiring compared to the Bolt EV.

• GM’s joint venture with LG Chem to develop and mass produce battery cells will drive cell costs

below $100 per kWh. Ongoing technological and manufacturing breakthroughs will drive costs even

lower.

A unique manufacturing partnership.

• GM’s EV battery cells will be mass produced at a $2.3 billion joint venture plant that GM and LG

Chem plan to build in Lordstown, Ohio.

• The plant, which will be about the size of 30 football fields, will have annual capacity of more

than 30 gigawatt hours and room for expansion.

• Site assessments and the permitting process are underway, and groundbreaking is expected to occur

in the spring of 2020.

• The joint venture is expected to create more than 1,100 new, good-paying jobs.

New technologies under development to improve charging, cycling, range, cost and battery life

include:

• Zero cobalt and zero nickel cathodes

• The use of electrolyte additives to heal cell “scratches" that reduce cycling

• Solid state batteries

Charging

GM’s Zero Emissions Vision: Vehicle Charging

Part of GM’s strategy to help create a mass market for EVs is to make home, work and public

charging quick, easy and efficient. Vehicles built on our all-new modular architecture are engineered for both alternating current (AC) and direct current (DC) fast charging.

• Ultium-powered EVs are designed for Level 2 and DC fast charging.

• Most will have 400-volt battery packs and up to 200kW fast-charging capability while our truck

platform will have 800-volt battery packs and 350 kW fast-charging capability.

• Our platform has the capability to charge over 100 miles of range in ten minutes.

GM has developed a wide range of tools to help more than 200,000 Chevrolet Volt and Bolt EV

customers find fast, affordable and convenient charging solutions.

• For the 80 percent of EV customers who charge at home, Chevrolet has partnered with Qmerit to

provide them with easy access to accredited home EV charging station installers in their area.

• To help customers “on the go" locate one of the 40,000-plus charging stations compatible with the

Chevrolet Bolt EV, GM has created the Energy Assist feature, part of the myChevrolet mobile app.

• The app also integrates real-time data from the EVgo and Chargepoint networks to help customers

locate open charging stations.

• New this year, owners can link their EVgo account to activate and pay for charging sessions at

eligible stations right from the app.

• GM is making charging for employees even more accessible with the addition of 3,500 new charging

connectors throughout its U.S. and Canadian facilities. This will triple the amount of charging

stations that GM currently provides.